- İstasyon Mah. Güngörmüş Sok. No: 13 Kartepe / Kocaeli

- info@erdoganendustri.com

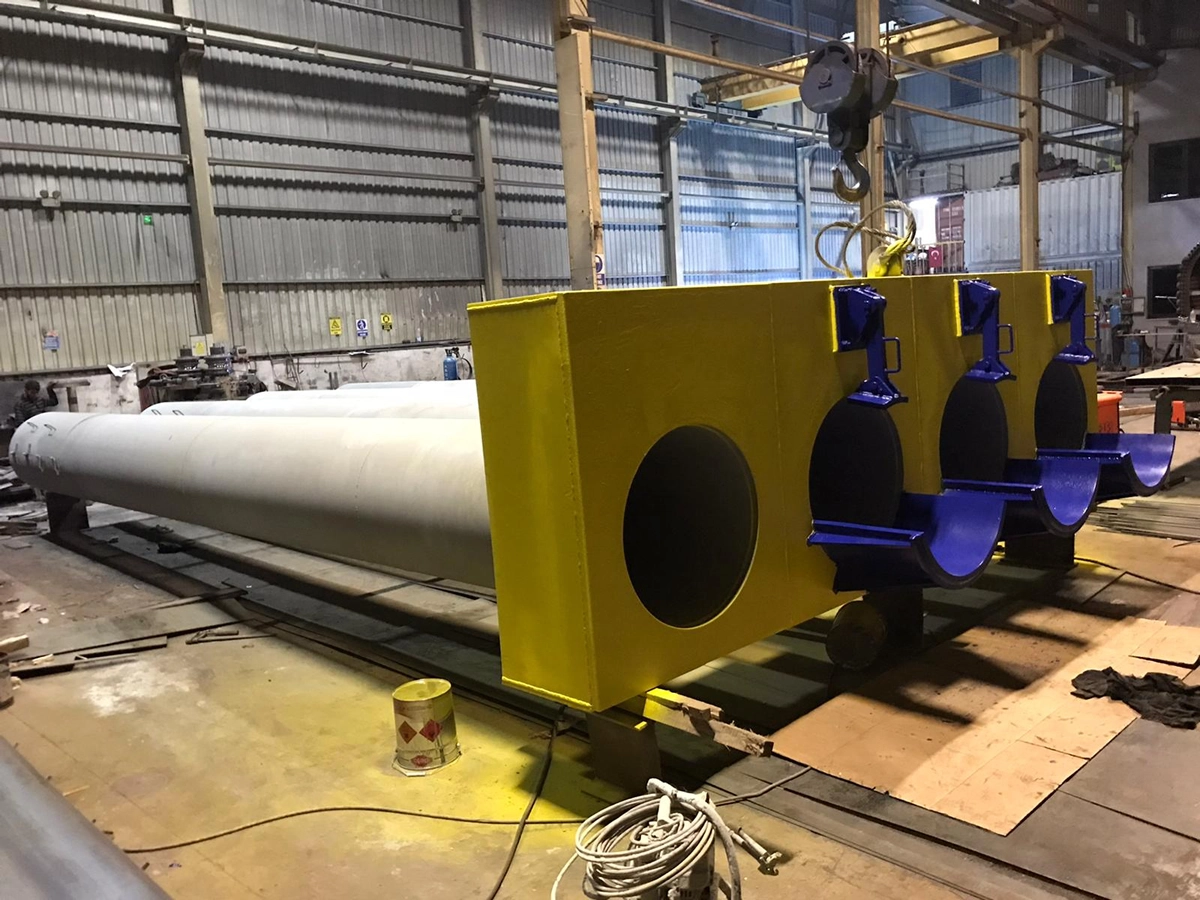

Water Cooled Elbows

Water Cooled Elbows

In our company, water-cooled elbows are a very big project and water-cooled systems consisting of other parts play an important role in the operation of arc furnaces. As a result, there are various types of water cooled systems. Some require very clean, high quality cooling water. Such systems work like a closed circuit and the water passes through very sensitive parts.

A brief description of pipe assembly and welding processes within the scope of the water cooled elbows project:

Pipe Assembly:

Pipe Selection: The first step is to select pipes with material properties suitable for the cooling system. The ideal pipe material should be a material with high thermal conductivity, durable and resistant to corrosion.

Pipe Cutting: The selected pipes are cut to specific dimensions using special equipment. The cutting process ensures that the correct dimensions are required for a compatible joining of elbows and other components.

Preparation of Elbows: Elbows are curved parts to be used at the joints of pipes. It should be ensured that these elbows are cut at appropriate angles and dimensions.

Welding and Adjustment of Elbow:

Preparation of Pipe Ends: Pipe ends should be prepared for welding.This means cleaning the ends, aligning them properly and adding special welding apparatus if necessary.

If you have problems with your water-cooled systems, if you do not want to experience production interruptions caused by leaks and also if you want to extend the life of your equipment, please consult us.

Turkish

Turkish